Hecla: Technology should retool, not replace, miners

Despite a lengthy, contentious and expensive strike, Hecla Mining Co. officials want to make something abundantly clear: They’re embracing advances in technology not to bypass contrary employees, but to strengthen the company for the long haul.

Workers willing to retool their skills aren’t just welcome to hop aboard; they’re key to Hecla’s long-term success.

“We’re not looking right now at replacing anybody,” Mark Board, Hecla’s vice president of technical services, said recently at the company’s headquarters in Coeur d’Alene. “The jobs over time will change. The job skills will change somewhat but the number of people should remain fairly constant.”

Hecla is a precious metals company with four mines: Lucky Friday in Mullan, where the United Steelworkers Union local 5114 struck in March 2017; Casa Berardi in Quebec; San Sebastian in Mexico; and Greens Creek Mine in Alaska.

While the Lucky Friday strike has affected about 250 miners and deprived the Silver Valley economy of perhaps its most powerful catalyst, Hecla’s acceptance of the need to adapt predates the strike by years. Last summer, Board summarized the big picture strategy to CIM Magazine.

“We’re not a huge company,” he said. “So rather than simply diving in and saying we want to automate everything in the mine, we looked at all of our operations and asked ourselves where our bottlenecks were, what made sense economically for a company our size and the type of mining we do.”

Luke Russell, Hecla’s vice president for external affairs, said adapting better ways has always been an industry staple. He pointed out that in the early 1900s, drilling for ore took a leap forward when compressed air began taking the place of picks, shovels and elbow grease.

“What used to take 15 guys now took three guys,” he said. “The other 12 didn’t lose their jobs. They did other things.”

Russell said that ideally, technology will lead to more jobs rather than reduce them. He used automated tellers in the banking industry as an example, noting that bank services expanded exponentially — generating many new jobs in mortgage lending and insurance, for example — when less time and fewer people were needed for jobs that could easily be automated.

Russell referred to the essential nature of leveraging technology for prosperity’s sake — that is, making sure the enterprise survives.

“‘If we don’t move forward with the technology and making money, well, then we are out of business…’” Russell said. Only that didn’t come from Russell, from Hecla President and CEO Phil Baker, or from anybody else around here.

“That’s a quote from Magnus Westerlund, the vice chairman of a Swedish union chapter that represents miners,” Russell said. Westerlund was quoted in a Dec. 27, 2017 New York Times article.

From the same article, Swedish minister for employment and integration Ylva Johansson said, “In Sweden, if you ask a union leader, ‘Are you afraid of new technology?’ they will answer, ‘No, I’m afraid of old technology.’ The jobs disappear, and then we train people for new jobs. We won’t protect jobs. But we will protect workers.”

The Swedish connection isn’t one of just words. For the past two years, Board said, he and others from Hecla have been working with a Swedish company, Atlas Copco, on developing the Hecla Mobile Miner for the Lucky Friday. The Mobile Miner uses steel disc ring rolling cutters on the circumference of a rotating wheel to crack and fracture rock so it can be transported via a conveyor to the back of the machine. The Mobile Miner is ideal for mechanical excavation of tunnels in hard rock, Board said. He added that the Mobile Miner’s target price is about $7.5 million.

The Mobile Miner is expected to be finished in March 2019 in Sweden. After it’s tested there, it will arrive in Idaho sometime later in the year.

“We’ll have to take it down in pieces and reassemble it,” Board said. Then testing in the Lucky Friday will take place, and by 2020, Board said, it should be in production mode.

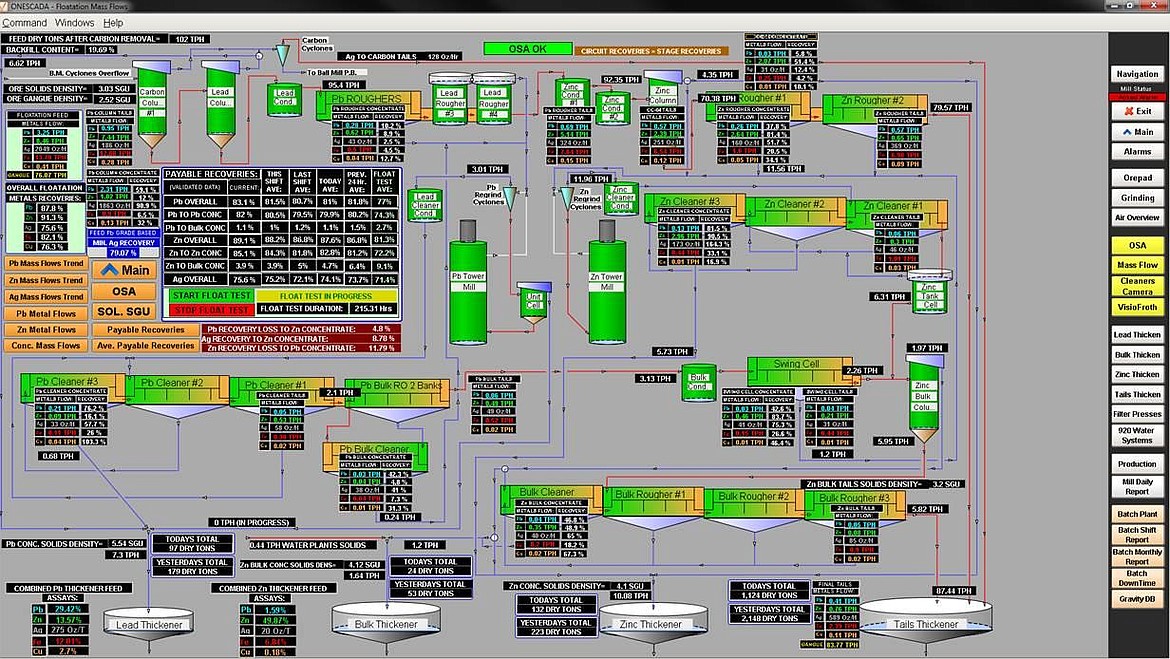

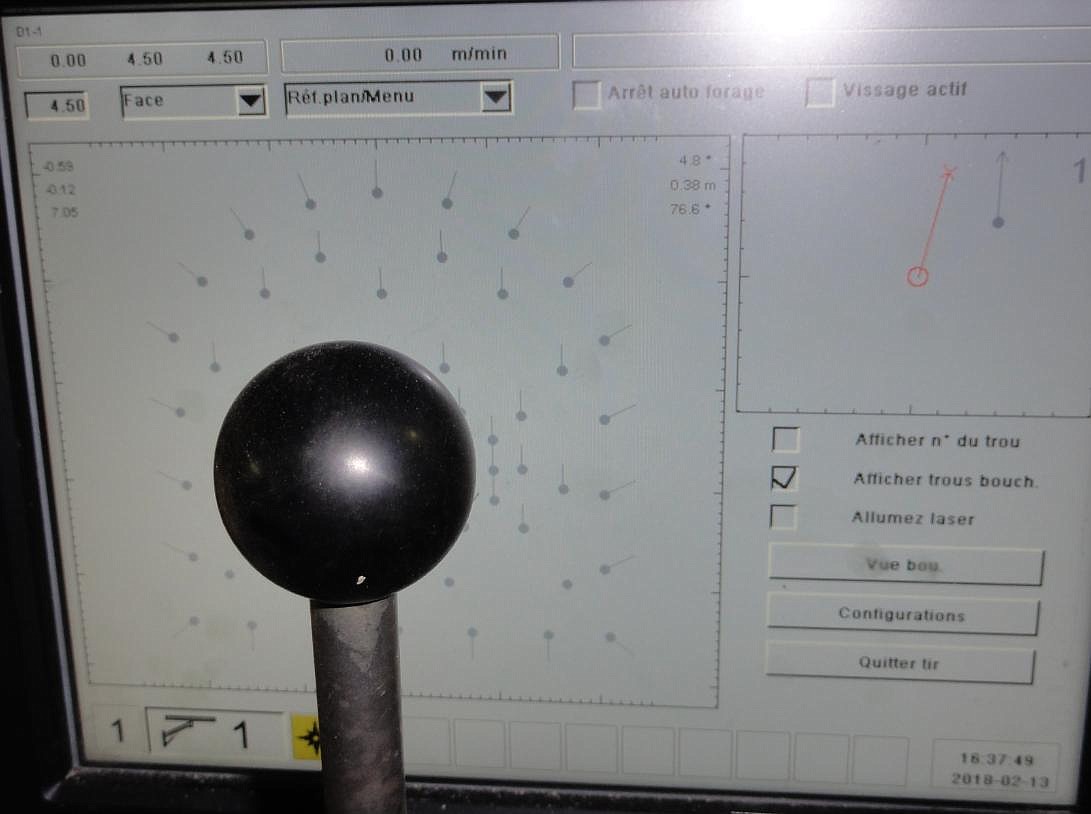

Another high-tech tool called a targeting system features designed 3-D face drill hole patterns that have been pre-programmed to control the movements and operations of “jumbo” drills used for tunnel excavation, Board said. The drill patterns can be transferred to the machine by thumb drive or wireless. Board said the drill automatically optimizes the rotational speed and force on drill bit to achieve faster drilling, straighter holes with lower wear on the drill. Hecla has re-equipped three drills at its Casa Berardi Mine in Quebec and is purchasing one for Greens Creek Mine off the coast of Alaska this year.

“At Casa Berardi we’re producing consistently repeatable tunnel profiles with better conformance to the designed tunnel shapes,” he said.

Another newer technology that Hecla is investing in is called ventilation on demand, or VOD, Russell said. The automated system stays aware of the current underground locations of people and mining machines on an ongoing basis, and accordingly adjusts the amount of air flow delivered to specified locations. The system helps maintain a safe working environment for miners while determining real-time personnel and machine locations and economically distributing the amount of air where it’s actually needed at that time.

“VOD can reduce overall power consumption and its costs,” Russell added.

When and where air volumes aren’t needed, he said, they aren’t supplied, allowing for reduced demand for power from the utility company and a dynamic reduction of the site’s carbon footprint.

“Power cost savings can help add years to the future mine life,” he said.

Key parts of the system include location sensors for people and equipment, status sensors for up-to-date gas concentrations, air flow, air temperatures and more), remote control devices for fans, and the communication network to connect it all. As of early 2018, the system was being implemented at Hecla’s Alaska operation, Russell said. He said it will be in the design stage later this year at the Quebec operation, and it will be studied for application at Lucky Friday and at the San Sebastian underground operation in Mexico in the future.

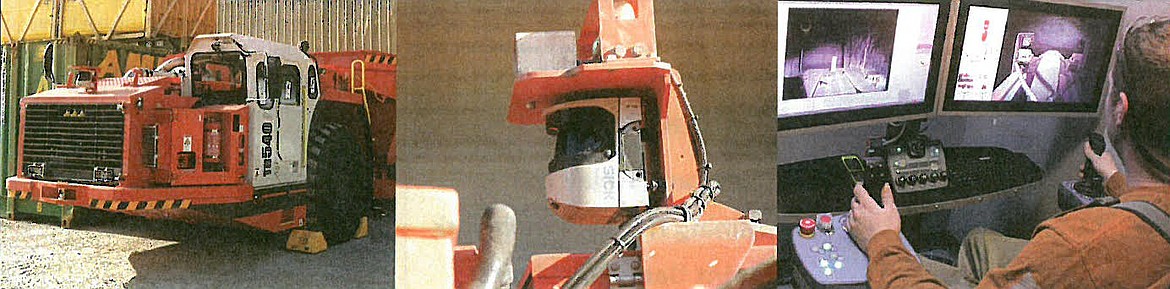

On a broader scale, Hecla is addressing another technological imperative: Installing fiber-optic cable with wireless hotspots throughout its mines. The objective is to gain continuous readouts of the location and mechanical condition of equipment underground, Board said, as well as to control equipment such as loaders and fans from remote locations.

“We can detect how much ore a truck is hauling, track engine hours for maintenance, and more,” said Board.

Rosser said it’s essential for safety and efficiency reasons to know where all the equipment and the people are underground.

“It’s about optimizing and conserving energy where we can,” he said.

Hecla is already either exploring or employing other equipment that is battery powered (eliminates diesel emissions), autonomous or semi-autonomous trucks and loaders, which makes mining safer and more productive. Rosser, a 33-year veteran of the mining industry who joined Hecla about two years ago, is immersed in studying how artificial intelligence and digitized data analysis can best be used toward optimization and energy conservation. He’s seeking to establish statistical trends about “what you’ve drilled and what it might lead to.”

Much of the investment, work and planning is aimed at simultaneously improving productivity, safety and the environment, the three agreed.

“The day may come,” Rosser said, “when no humans will need to go underground.”